Making of Custom Shoes: An Insight into the Shoe-Making Process

Shoes are a key part of a human attire. If you have a look around, either rich or poor you will not find anyone without a pair of shoes. As clothes are for body likewise shoes are for feet, an essential basic necessity.

As per a survey an average man owns 12 pairs of shoes in his entire life whereas an average woman owns 27 pairs. When all the humans on earth are consumers of a thing, it definitely means there is a worldwide production required.

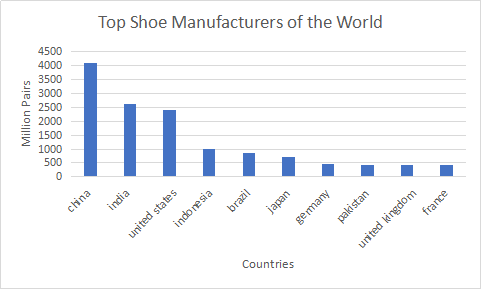

China and India are world footwear giants producing millions of shoe pairs annually. As per a report, in 2018, China produced 4110 million pairs of shoes. Thus, rightfully sitting on top of the list of top ten shoe manufacturers of the world.

Here is a list of top ten countries with highest production of shoes worldwide:

Intensive shoe making process in China:

China has worked really hard over the years and changed their economic status in the world. They were one of the poorest countries in the world and now they are among the richest. The credit goes to their exports going all across the world.

China shoe manufacturers play a major role in the success. China shoe manufacturers have led the market since many years now and ass per marketing experts they will continue to lead in the coming years too. In 2016, China alone exported shoes worth $47 billion. 60% of world footwear market is led by China.

China makes shoes for the world’s high-end brands like Balenciaga, Prada, Armani, Burberry and Vismvim to name a few. World’s leading shoe brands have shifted their manufacturing units to China now like Nike, New Balance, Sketchers, and Under Armour. The reason of shifting is the cheap workforce in Chinese market. The brands came to China and brought with them the modern technologies and ideas. China and the world’s leading high end shoe brands are now thriving together in a coalition.

So, now Chinese footwear market is an amalgamation of traditional shoe making skill and modern ideas & technology. Importers around the world can explore an array of options here. In today’s fast paced world, China is the best marketing incubator for small businesses.

Insights Into the Shoe-Making Process:

Have you ever looked at your shoes and wondered how shoes are being made around the world? It is not as easy as it may seem too many. In fact, it is a very detail oriented and intricate work.

Shoe making is an art and a skill in itself. It has been passed down through generations and with time has been beautified by the modern touch.

The shoe making process varies according to the shoe type. Basic procedure is same but a stiletto and a sneaker cannot be made in the same way. Both involve a different number of steps and a process altogether.

Let’s delve into the process of shoe making:

- Designing: the first and the foremost step is making design of shoe according to the desired type of shoe. This is also referred as sketching. It is usually done by hand or computer. It must include shoe design and shoe lasts.

- Cutting: next comes cutting. After the sketches have been made, it is time to cut the material of shoe as per layouts. Different parts are cuts individually.

- Stamping: at this stage, the cut pieces are marked so ass to avoid confusion at later stage. The attachment parts of the cut out are marked. The edges of cut outs which are to be joined together are thinned. If there is some punching and decorations in the shoe design they are also marked.

- Sewing: the cut pieces are then sewn together. Firstly, the upper layer is sewn and then comes the lining. Toe caps and counter are added. The sems are neatened afterwards. Then eyelets are punched.

- Assembling: At first, insole is attached below the shoe last using three nails. Then rubber ridge is attached. later shoe shaft is adjusted and fixed. The welt is then stitched to both the linings. A shank is also put at this stage. Lastly seam holes are covered. This is called assembling.

- Shoe lasts: shoe last is the most important part of a shoe making process. It is a 3D mould like the shape of human foot. A perfect fitted shoe is only possible if there is a shoe last used in the process. They have been part of shoe making process since ancient times.

Making of Custom Shoes:

Custom shoe manufacturers are those shoe manufacturers who make shoes individually for customers catering to their demands and needs. Here’s a map of custom shoe making process:

- Measurement and style: the best shoe is the one which fits perfectly. So first step is taking accurate measurements from all angles.

- Shoe last: a shoe last is chosen and amendments are made as needed.

- Cutting: the designer then cuts the layouts on papers and then on leather or desired material.

- Assembling: the closer then assembles the shoe parts together.

- Trial: a trial is done at the last to see if the shoe fits.

Shoe Factories In Guangzhou, China:

Guangzhou is the trading capital of china. It has leading footwear sales in the country since years now. Best china shoes wholesale markets are also located in China. if you are looking to import shoes from china, Guangzhou is the place for you. You will find the best whole sale shoe suppliers and manufacturers here. Some of the leading names are:

- Marcusius China Shoe Manufacturers

- Guangzhou Dasen shoe Factory

- Guangzhou Aodi shoe Factory

- Hongmian Liubing Shoes Factory

- Shangyi Shoes Factory

Marcusius China Shoe Manufacturers is our top pick from the brands as it is a professional china shoe manufacturer dealing in all kinds of shoes like casual shoes, Goodyear shoes, exotic skin sneakers, lizard shoes, ostrich shoes, alligator shoes, crocodile shoes and dress shoes. The goal is to make business easy for their clients.